Wilsion Quality Control System

We value the quality as the company's lifeline,so we strictly do the inspection and make the promise as follow,

1. All the products should be done 100% inspection.

2. All the contracts should be attached with the technical specification as the chemistry,tolerance,hardness,mechanical properoties,non-metallic Inclusion etc., Our quality engineer would 100% execute it completely.

3. All the contracts 100% had the official quality test report and MTC.

4. Any quality claims would be responsible within 24 hours.

IQC(Incoming Quality Control)

Raw materials for steel production inspection are carried out to make first important step of quality control.

IPQC(In-process Quality Control)

According to production plan,IPQC are carried out to ensure production can meet designated technical requirements.

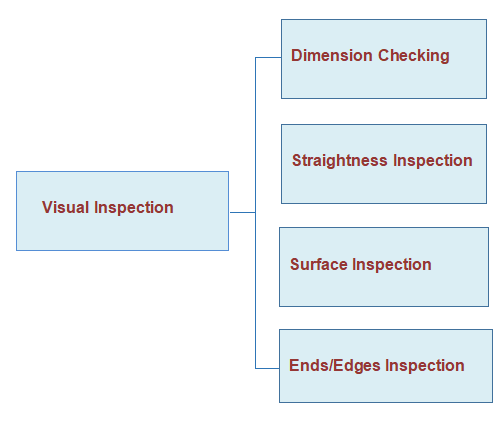

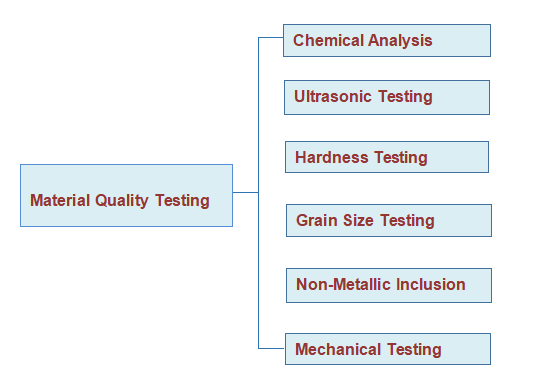

FQC(Final Quality Control)

After the manufacture of the products,Teamwise will carry out quality inspection for final products,for following items:Chemical compoistion analysis,demension checking,hardness,surface,mechanical properies testing and other testing items.Testing results for each piece will be recorded to ensure all the products meet customer's requirements.

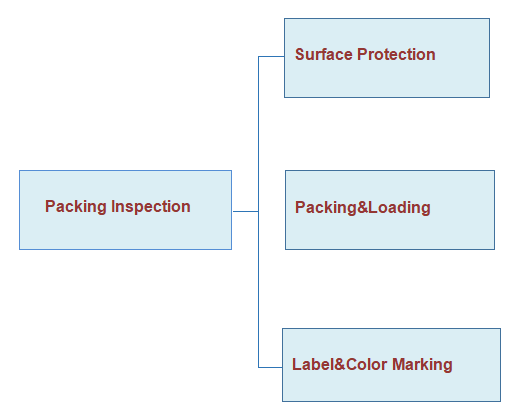

OQC(Outing-going Quality Control)

As per customer's order requirement,Teamwise marks color coding,bundling packing and other identification and loading requirement,so that the customers can unload the materials safely and efficiently,not matter in the destination port or company warehouse.

We value the quality as the company's lifeline,so we strictly do the inspection and make the promise as follow,

1. All the products should be done 100% inspection.

2. All the contracts should be attached with the technical specification as the chemistry,tolerance,hardness,mechanical properoties,non-metallic Inclusion etc., Our quality engineer would 100% execute it completely.

3. All the contracts 100% had the official quality test report and MTC.

4. Any quality claims would be responsible within 24 hours.

IQC(Incoming Quality Control)

Raw materials for steel production inspection are carried out to make first important step of quality control.

IPQC(In-process Quality Control)

According to production plan,IPQC are carried out to ensure production can meet designated technical requirements.

FQC(Final Quality Control)

After the manufacture of the products,Teamwise will carry out quality inspection for final products,for following items:Chemical compoistion analysis,demension checking,hardness,surface,mechanical properies testing and other testing items.Testing results for each piece will be recorded to ensure all the products meet customer's requirements.

OQC(Outing-going Quality Control)

As per customer's order requirement,Teamwise marks color coding,bundling packing and other identification and loading requirement,so that the customers can unload the materials safely and efficiently,not matter in the destination port or company warehouse.